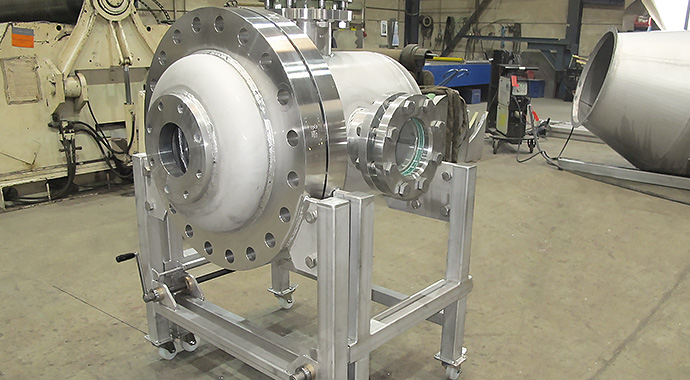

Pressure vessels are an indispensable part of many industrial processes. They come in various shapes and sizes and are used to store, transport or process liquids, gases and vapours under high pressure. Classic examples of pressure vessels include agitator vessels, process vessels, vessel columns and shell and tube heat exchangers.

Agitator vessels are used when a homogeneous mixture of liquids or solids is to be achieved. They are equipped with an agitator that mixes the components evenly. Process vessels, on the other hand, are used to store or process liquids or gases. They can be used in the chemical industry or food production, for example.

A double jacket can provide additional safety in many pressure vessels. This is a second jacket that is placed around the actual container and into which heat or cold can be introduced. This allows the temperature of the vessel to be controlled, which is important in many processes.

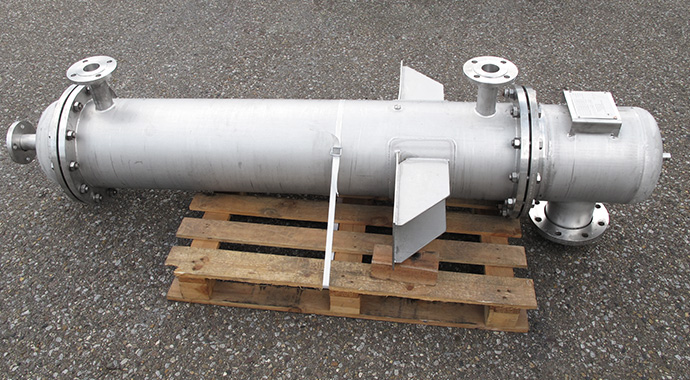

Shell and tube heat exchangers are another example of pressure vessels. They are used to transfer heat from one medium to another. Here, a tube bundle is inserted into the vessel containing the medium that is to give off heat. The medium that is to absorb the heat is then passed through the vessel.

Container columns, on the other hand, are found particularly in the chemical industry. They are used to separate gases or liquids by condensing or evaporating them in several stages. Various packing materials or packings are often used in this process.

It is important that pressure vessels always comply with the applicable standards and regulations to ensure the safety of people and the environment. When buying a pressure vessel, therefore, only products from reputable manufacturers should ever be considered. Regular maintenance and inspection are also essential to ensure the proper functioning of the vessel.

Caution: giant product world approaching

Please contact us